The main topics:

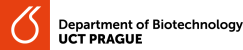

- Aerobic and anaerobic cultivation of bacteria, yeasts, and filamentous fungi

- Production of primary and secondary metabolites

- Characterization of microbial populations by use of fluorescent techniques

- Molecular biology of solventogenic clostridia

- Production of secondary metabolites by the fungus Monascus

Staff

|

Main research topics

Production of biofuels and bioplastics

Biotechnological production of biofuels (ethanol and butanol) and bioplastics precursors (succinic acid, lactic acid) by using first and second generation feedstocks. Design of fermentation process, selection of suitable feedstock, cultivation conditions and process arrangements (batch, fed-batch, continuous) for maximum yield and process productivity.

Molecular biology of solventogenic clostridia

Analysis of gene function and comparative genome studies focused on the basic research of the organic solvents biosynthesis during acetone–butanol–ethanol (ABE) fermentation. Methods for genetic manipulation of solventogenic clostridia development, qPCR based gene expression monitoring and description of the biobutanol biosynthesis on the molecular level. Endospore formation research of Clostridium bacteria.

Analysis of microbial populations on the single cell level

Detailed analysis of microbial populations using fluorescent microscopy, flow cytometry, and fluorimetry. Analysis of cell viability, growth rate, enzyme activities, concentration of intracellular compounds (DNA, NA, proteins, PHA, GFP, …) and other cell functions using selective staining with fluorescent probes. Measurement of these parameters for bacterial and yeast populations within the cultivation process under the influence of stress factors and antimicrobial agents.

Production of recombinant proteins by microbial host strains

Use of continuous processed data for the design of fed-batch processes for high cell density cultivation for production of recombinant proteins. Analysis of online and offline variables, design of suitable process arrangement.

Processing of waste materials from agriculture and industry into value-added products

Physico-chemical and/or enzymatic processing of lignocellulosic materials (wheat, wood, etc.) and keratin rich material (e.g. chicken feathers) and use of substrates based on nutrients derived from these feedstocks for biotechnological production of value-added products, e.g. biofuels (bioethanol, biobutanol), precursors of bioplastics (lactic and succinic acids), and others.

Production of secondary metabolites

Production of oligoketide pigments by Monascus purpureus by solid state or submersed cultivation. Optimization of cultivation conditions for preferential biosynthesis of yellow pigments (monascin and ankaflavin). Isolation and determination of pigments, citrinin, and monacolin K. Testing the effects of yellow pigments on the rat metabolic syndrome (in cooperation with ICEM).

Cooperation

- Zurich University of Applied Science, Swiss

- University of Insubria, Varese, Italy

- Institute of Nuclear and New Energy Technology, China

- Huazhong Agricultural University, Wuhan, China

- Auburn University, USA

- Ústav biomedicínského inženýrství, VUT Brno, Czech Republic

- Institute of Microbiology of the ASCR, v. v. i., Praha, Czech Republic

- Lonza Biotech, Kouřim, Czech Republic

- The Crop Research Institute, Praha, Czech Republic